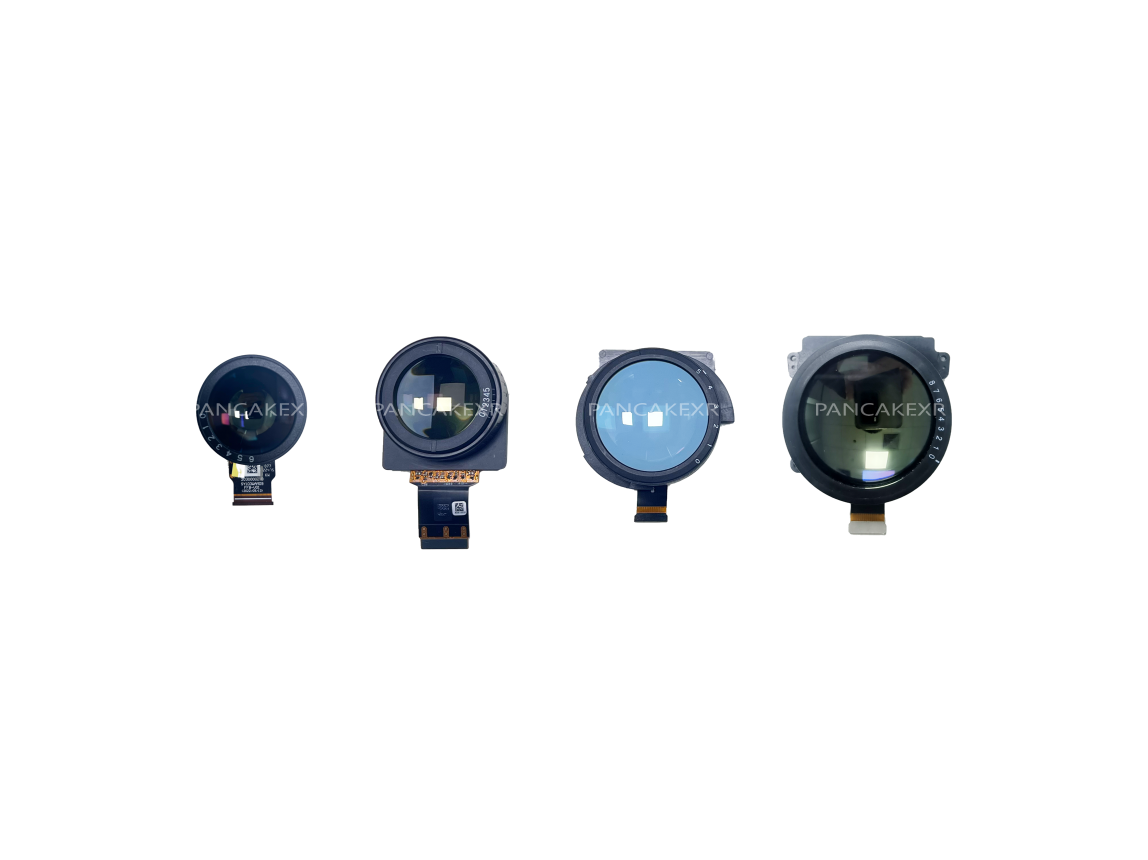

Optical Customization Capabilities

With expertise in the three stages of optical development - Aspheric lenses, Fresnel lenses, and Pancake solutions. We understand the market's demand for thinner, lighter designs, superior imaging quality, and improved comfort. By leveraging appropriate optical technologies, we design products that meet these requirements, ensuring a high-quality VR experience for our customers.

1.03”Micro-OLED

PANCAKE Lens

2560*2560

1.35”Micro-OLED

PANCAKE Lens

3552*3840

2.1"Fast-LCD

PANCAKE Lens

2280*2280

2.56"Fast-LCD

PANCAKE Lens

2160*2160

Screen Recommendation

-

Fast-LCD

Fast-LCD is the primary screen choice for current VR headsets. It offers advantages such as high volume production, stability, yield, excellent performance, and cost-effectiveness. However, it does have limitations in terms of response time and power consumption. Fast-lcd

Fast-lcd

-

Size

2.1"

-

Resolution

1600*1600

-

Refresh Rate

90Hz

-

PPI

1058PPI

-

NTSC Ratio

70.8%

-

Size

2.56"

-

Resolution

2160*2160

-

Refresh Rate

90Hz

-

PPI

1192PPI

-

NTSC Ratio

85%

-

-

Micro OLED

In comparison, Micro OLED offers several advantages over Fast-LCD, including high resolution, brightness, refresh rate, and lightweight design. It reduces weight by more than 50% and has lower power consumption compared to traditional display devices. Micro-OLED

Micro-OLED

-

Size

1.35"

-

Resolution

3552*3840

-

Refresh Rate

90Hz

-

PPI

3882PPI

-

NTSC Ratio

96%

-

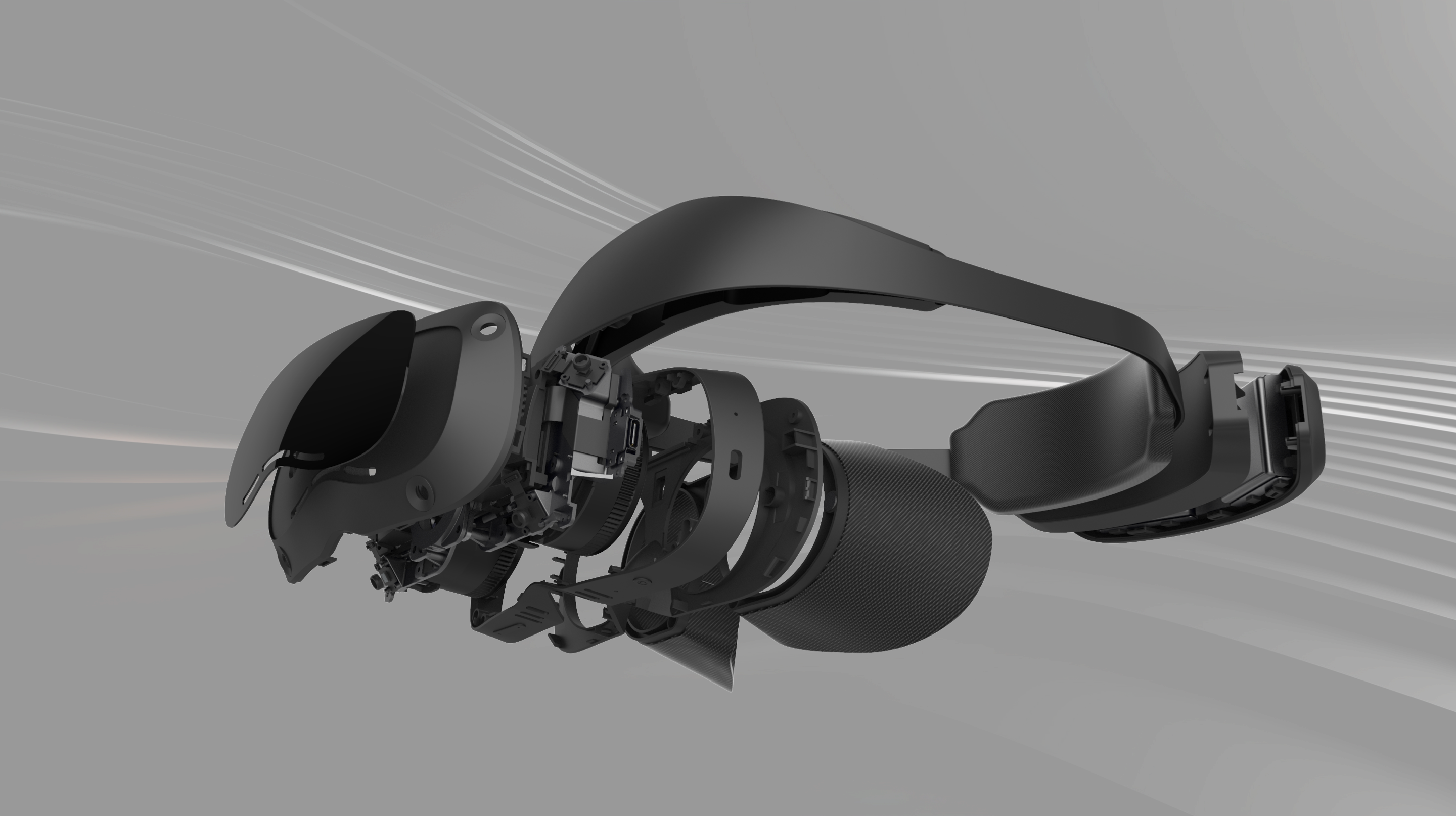

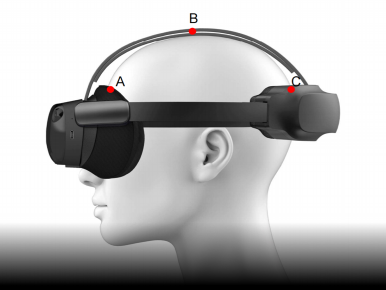

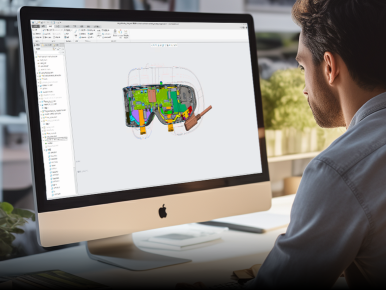

ID/MD Customization Capabilities

We specialize in providing top-tier ID/MD customization services. The ergonomic design of MR/VR/AR devices plays a pivotal role in their comfort. With over 10 years of experience in MR/VR/AR devices design, our ID designer team possesses extensive expertise. They have accumulated comprehensive head human-machine data, enabling them to create designs that precisely match customers' requirements and visions.

We have a profound understanding of market demand and user behavior, and approach product design from a human-machine perspective, emphasizing aesthetics and user-centricity. Concurrently, we prioritize efficient collaboration between design and production, ensuring smooth project progression.

Hardware Customization Capabilities

We have engineers who have worked in the XR field for more than 10 years and have mature hardware product customization capabilities. We have good cooperation with leading suppliers to ensure that we can provide customers with high-quality solutions. Our unwavering commitment is to deliver high-quality design services, seamlessly bridging the gap between design and production to meet and exceed customer needs and expectations.

Software Customization Capabilities

For software solutions, we can provide a full set of customized services, such as system customization, including ROM, logo, UI, and launcher. Support customization of auxiliary tools, including VR assistant, streaming, projection, etc.

Manufacturing Capabilities

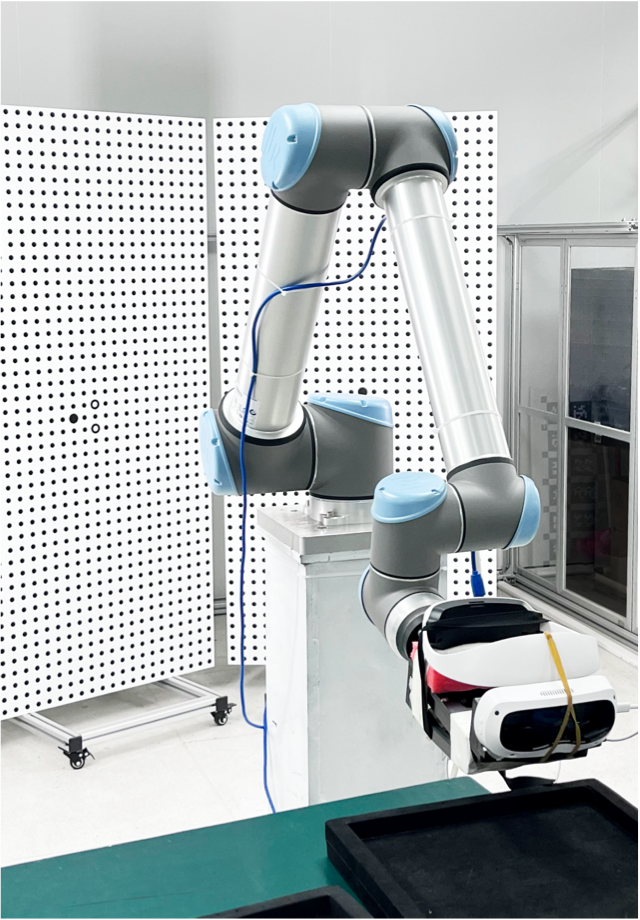

PANCAKE XR, as a subsidiary of Skyworth Group, benefits from a robust shared supply chain system. This system ensures quality control across the entire process, from raw material procurement to manufacturing and final delivery. We possess advanced manufacturing capabilities and integrate German and Japanese standard practices.

Our comprehensive lean manufacturing management system strengthens our advanced manufacturing capabilities. We have established industry-leading intelligent production lines and logistics systems, specifically designed to overcome challenges in robot collaborative control, flexible operations, visual inspection, and intelligent logistics. These investments enhance our operational efficiency and reinforce our position as a leader in advanced manufacturing management.

Quality Assurance Capabilities

In order to ensure that our products operate under various conditions, we will conduct the following tests: standard quality inspection, comprehensive quality inspection, comprehensive optical test, mechanical performance test, robustness test, durability test, etc.